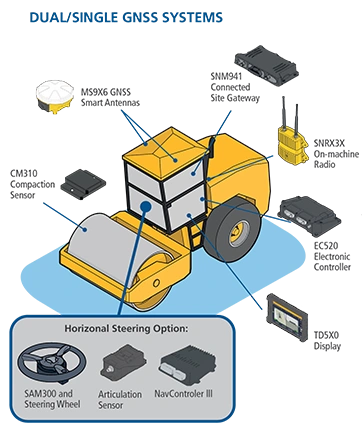

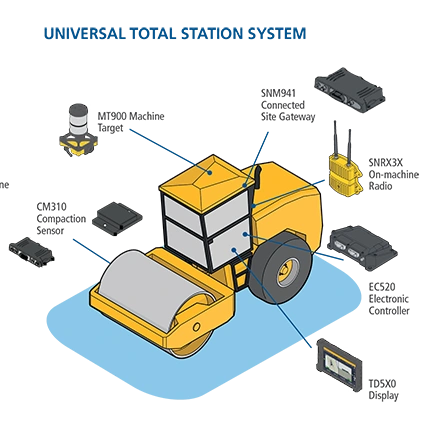

TRIMBLE EARTHWORKS FOR SOIL COMPACTORS

FOR A PERFECT FINISH

Trimble Earthworks for Soil Compactors is a specialised grade control system for vibratory and pneumatic soil compactors. It delivers real-time feedback, helping operators achieve optimal compaction efficiently, accurately, and consistently.

Learn More – Trimble Earthworks for Soil Compactors PDF